How to cut reinforced concrete

Share

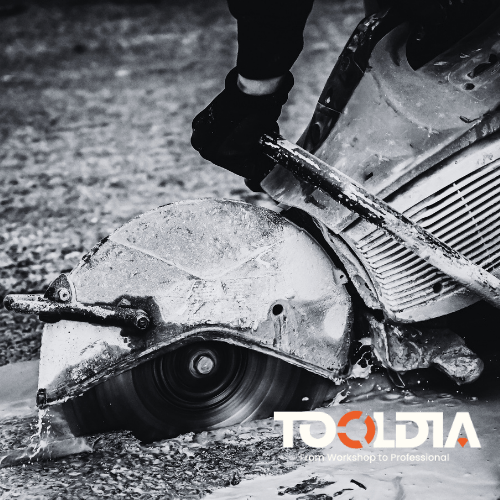

How to Cut Reinforced Concrete: Techniques and Tools to Achieve Perfect Results

Cutting reinforced concrete is a challenging task. The presence of steel reinforcement bars (rebar) embedded within the concrete significantly increases the complexity of the cutting process. However, with the right diamond tools and appropriate methods, you can achieve precise, clean cuts. In this article, we will explain clearly how to cut reinforced concrete, highlighting common issues and their solutions.

Common Challenges and Solutions

Firstly, let's understand the main difficulties encountered when cutting reinforced concrete:

-

Blade wear and damage: The embedded rebar can cause rapid wear on diamond blades.

-

Excessive vibration: Cutting through steel reinforcement often results in heavy vibrations, affecting precision.

-

Overheating: Friction against steel bars can cause excessive heat, potentially damaging both blade and material.

Fortunately, selecting the right diamond blade and adopting proper cutting techniques solves most of these problems. Below we detail precisely how to cut reinforced concrete using different machines and diamond blades.

Cutting Techniques with Angle Grinders

Angle grinders (flexible grinders) are commonly used for small or precise reinforced concrete cuts. However, due to their handheld nature, the right diamond blade selection is crucial:

-

Diamond blade type: Choose segmented diamond blades, as they effectively dissipate heat and handle the vibration caused by steel reinforcement.

-

Diameter: Typically, diameters from 115 mm to 230 mm are ideal for standard angle grinders.

Additionally, always ensure the blade rotates at the manufacturer's recommended RPM to reduce blade wear and achieve cleaner cuts.

How to Cut Reinforced Concrete with Power Cutters (Handheld Cut-off Saws)

Power cutters (also known as handheld cut-off saws) deliver higher cutting power than angle grinders. Therefore, they're ideal for medium to large-scale cutting operations:

-

Diamond blade type: Select high-quality segmented or turbo-segmented diamond blades. These types allow fast cutting speed, efficient heat dissipation, and reduced vibration.

-

Diameter: Blades ranging from 300 mm to 400 mm are most common for power cutters.

Moreover, ensure adequate water cooling during cutting. Water prevents overheating, maintains blade sharpness, and reduces dust production significantly.

How to Cut Reinforced Concrete with Floor Saws (Joint Cutters)

Floor saws (joint cutters) are typically used for cutting reinforced concrete slabs or pavements. Because these machines handle deep cuts, specific blade characteristics are necessary:

-

Diamond blade type: Use large-diameter segmented blades with thicker segments. These blades efficiently manage the depth and durability requirements for concrete pavement cutting.

-

Diameter: Common sizes range from 350 mm up to 1400 mm, depending on the depth of cut needed.

Furthermore, proper alignment and consistent speed ensure smooth cuts and blade longevity. Thus, always operate these machines according to manufacturer guidelines.

Effective Use of Wall Saw Machines

Finally, wall saw machines specialize in vertical reinforced concrete cutting, typically used for structural openings or demolition purposes:

-

Diamond blade type: Specially designed segmented blades with high-quality diamond segments are recommended. These blades ensure maximum durability and clean cutting even through dense rebar structures.

-

Diameter: Wall saw blades range commonly from 600 mm up to 2000 mm.

Due to the large blade diameter, continuous water cooling and precise machine control are essential to maintain accuracy and prevent overheating.

Essential Tips on How to Cut Reinforced Concrete Successfully

To achieve perfect results and avoid common mistakes, follow these practical tips:

-

Use Water Cooling: Always use a water cooling system to minimize heat, protect your diamond blades, and reduce dust exposure.

-

Inspect Blade Condition Regularly: Immediately replace blades showing excessive wear, damaged segments, or uneven edges.

-

Maintain Correct RPM: Operate your diamond blade within the manufacturer's recommended RPM range to enhance efficiency and blade lifespan.

-

Apply Steady Pressure: Apply uniform, consistent pressure without forcing the blade. Allow the diamond segments to do the cutting effectively.

Conclusion

In conclusion, understanding how to cut reinforced concrete involves selecting suitable diamond blades, using appropriate cutting machines, and applying correct techniques. By adopting these recommendations, you can effectively overcome common reinforced concrete cutting challenges, ensuring precision, safety, and efficient project completion.

For top-quality diamond blades designed specifically for reinforced concrete cutting, consider visiting tooldia.com to explore a specialized selection suited for your cutting needs.